The shell of a pressing roller is a replaceable outer part of the roller that directly contacts the raw material, helping to form it into finished pellets. The choice and condition of the shells significantly affect pelletizing efficiency.

We manufacture roller shells of any size and type for all pellet mill models available on the market, using only the highest quality materials.

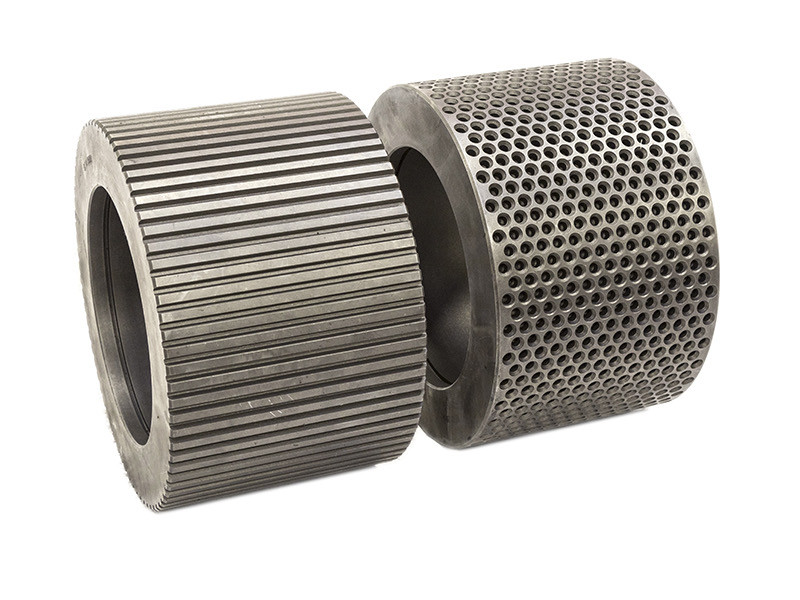

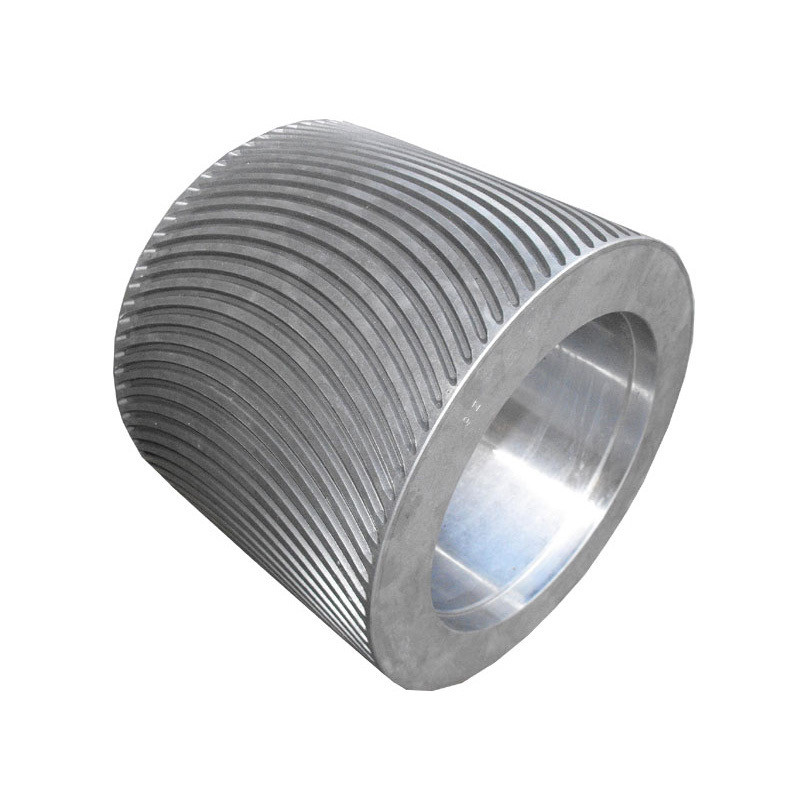

In worldwide practice, there are dozens of types of roller shells, each suitable for specific operating conditions:

- Dimpled.

- Straight corrugated (end-open/end-closed).

- Angled corrugated (end-open/end-closed).

- Dimpled end-closed.

- Chevron corrugated pattern.

- Curved corrugated pattern.

- Corrugated and Dimpled pattern.

- Others.

Choosing spare parts for your pellet mill is an investment in the stable and efficient operation of your production. High-quality roller shells help reduce maintenance costs, improve productivity, and extend the service life of your equipment. Make the right choice – choose reliable shells that meet your specific needs!

Contact us for a consultation and to order roller shells that are compatible with your pellet mill.